Threading its way into manufacturing history, a Chinese humanoid robot called KR-1 has achieved the world’s first two-handed stitching operation. This breakthrough marks a significant advancement in robotics, as the machine perfectly manipulates fabric with both hands simultaneously. The robot was developed by a leading Chinese tech firm with the specific goal of taking over precision tasks currently performed by human seamstresses.

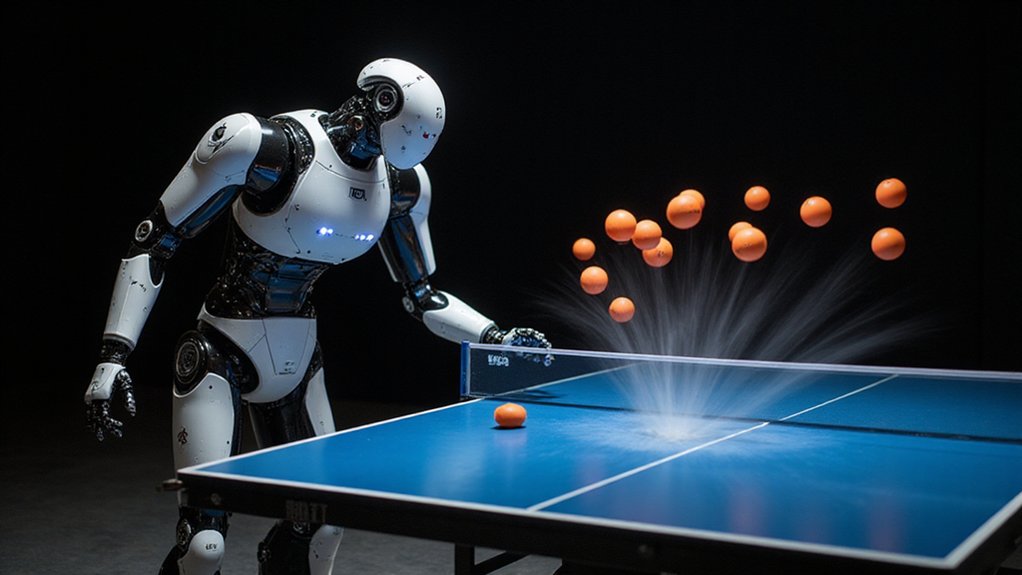

The KR-1’s success stems from its innovative learning method called kinesthetic teaching. During training, a human operator guides the robot’s arms while it’s in a compliant mode. The robot records these movements through its RGB camera, creating a database that links visual inputs to physical responses. This approach allows the robot to learn without explicit programming.

Kinesthetic teaching transforms robots from programmed tools to observant apprentices, learning through guided human touch.

After multiple demonstrations, the robot establishes connections between what it sees and how it should respond. It recognizes fabric edges, learns when to pull materials, and determines how to align pieces properly. Unlike traditional robots, the KR-1 doesn’t need specific programming for each new task – it learns by observation.

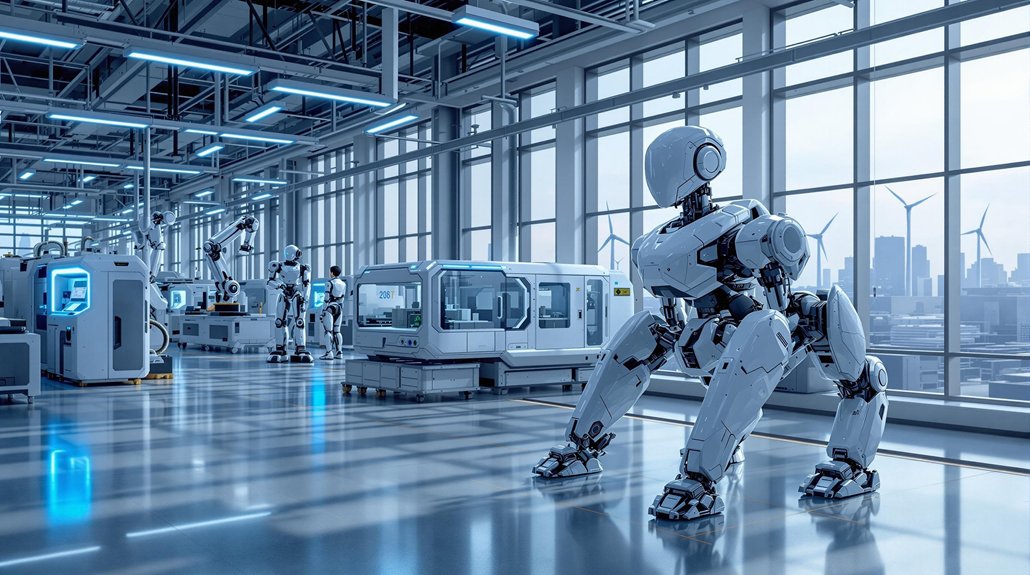

The robot’s muscular design is key to its fabric manipulation abilities. It can perform complex tasks like folding towels and can quickly swap tools for different jobs. With an estimated cost of several hundred thousand dollars, the KR-1 represents a substantial investment for manufacturers seeking automation solutions. The KR-1 demonstrates remarkable adaptability when handling soft materials like towels, despite their continuously changing shapes during manipulation. However, experts warn that these systems could be vulnerable to cyberattacks that might compromise their operation or safety. Some versions even feature a six-arm design for advanced multi-tasking capabilities.

The KR-1 is already being pilot tested at Midea’s Wuxi washing machine factory, where it’s expected to speed up production changeovers by 30%. It’s replacing entire teams of workers and single-purpose machines in high-end appliance production.

This development is part of China’s broader push into high-performance humanoid robotics. The KR-1 joins other advanced models like the UBTECH Walker S, which is partnering with Zeekr for manufacturing applications.

As these robots move from prototypes to practical deployment, they’re changing the landscape of industrial production. Human seamstresses may soon find themselves working alongside or even being replaced by these dexterous mechanical counterparts.

References

- https://www.youtube.com/watch?v=3G4yYe5gPSs

- https://interestingengineering.com/ai-robotics/muscular-humanoid-robot-folds-towel-autonomously

- https://humanoidroboticstechnology.com/articles/top-10-chinese-humanoid-robots-of-2025/

- https://interestingengineering.com/ai-robotics/security-flaw-could-allow-hackers-control-robots

- https://www.youtube.com/watch?v=wbLl3aSOzoc