NVIDIA’s Mega Omniverse Blueprint is transforming industries through digital twin technology. Companies are creating virtual replicas of robots that update in real-time with sensor data. This technology allows businesses to test and optimize AI-powered robot fleets without real-world risks. The market is growing rapidly, with projections reaching $73.5 billion by 2027. Industries from manufacturing to healthcare are seeing reduced development time and lower costs. The digital transformation continues to accelerate across global operations.

Every day, more companies are turning to digital twin technology to transform how they design, test, and maintain products. These virtual replicas of physical objects or systems update in real-time using data from sensors and connected devices. The global market for this technology is growing fast, with experts predicting it will reach $73.5 billion by 2027 and showing 60% annual growth in adoption over the next five years.

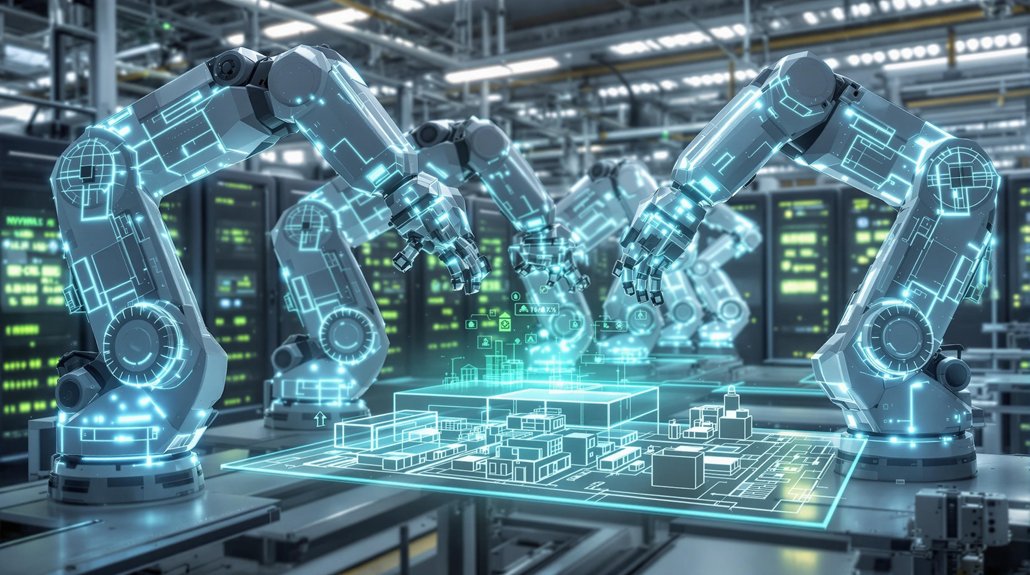

NVIDIA’s Mega Omniverse Blueprint is making waves across industries. This framework helps companies develop and test AI-powered robot fleets in virtual environments before real-world deployment. It combines NVIDIA’s computing power, artificial intelligence, and Omniverse technologies to enable continuous testing and optimization for various robots including automated mobile robots and humanoids. The blueprint leverages Omniverse Cloud Sensor RTX APIs for simultaneous rendering of sensor data from multiple sources.

Manufacturing companies use digital twins to improve production and quality control. In healthcare, the technology creates personalized treatment plans and monitors medical devices. Similar to how AI enhances diagnostics in medical imaging, digital twins provide crucial visualization capabilities. Aerospace firms simulate aircraft performance and predict maintenance needs. Energy companies optimize power grids, while supply chain businesses reduce costs and improve operations.

The benefits are clear. Companies gain a complete view of their processes, predict maintenance needs before breakdowns occur, use energy more efficiently, and test scenarios without real-world risks. The ability to simulate failure scenarios allows businesses to identify potential issues before they cause costly downtime. Some users report cutting development times in half. In supply chains specifically, digital twins can reduce transportation costs by up to 10% and increase order fulfillment by up to 20%.

However, challenges exist. Companies must manage data security risks, high initial costs, complex data streams, and the need for specialized skills. Integration with existing systems can also be difficult.

Looking ahead, digital twins will increasingly incorporate AI and machine learning for better predictions. The technology will expand to new industries, make greater use of cloud computing, and benefit from more advanced sensors. Efforts to standardize frameworks will help more businesses adopt this transformative approach to designing, testing, and optimizing their operations.